No matter how big or complex the project is, we keep it simple: quality counts. Our knowledgeable procurement managers ensure fair pricing without compromising on standards. Our technologically advanced project control systems satisfy the high demands of quality international and domestic clients.

Namibia’s largest SMP projects.

Regional Know-How

25+ years of knowing what to do and, crucially, what not to do to guarantee project delivery in Namibia.

>250 Employees,

>180 Machines

Our equipment fleet and project-tested teams have the size to handle complex projects, reducing project risks associated with the need to sub-contract.

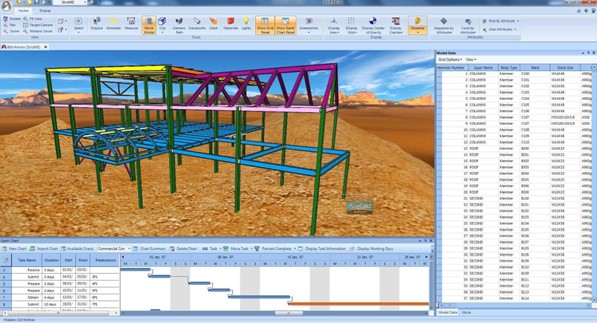

Advanced project controls systems

We employ an integrated management system (StruMIS) with barcode scanning, allowing clients to monitor the progress of projects from detailing to site installation, using a 3D BIM viewer.

One integrated, versatile team

capable of handling the full spectrum of earthworks,

civils and structural steel tasks.

Lower costs higher quality

From an integrated project team that reduces the need to subcontract, to an integrated project management partnership that overcomes delays caused by fragmented steel deliveries, we cut cost by cutting inefficiency.

Safer sites smoother projects

Frequent safety audits are conducted on site during every project and our teams receive regular training to guarantee compliance. Investing heavily in best practices protects our teams and our projects from costly delays.

Client satisfaction is our key competence.

We measure the success of a project by the level of client satisfaction achieved. That’s down to the experience of well-drilled teams, able to troubleshoot and keep forging ahead when inevitable challenges arise.

Project Showcase

We offer integrated, turnkey solutions for Structural, Mechanical, Platework, and Piping (SMPP) projects in Namibia. We guarantee project delivery and end-to-end execution to the highest standard.

This project was another successful collaboration with our South African Steel Fabricating partner Viva Engineering.

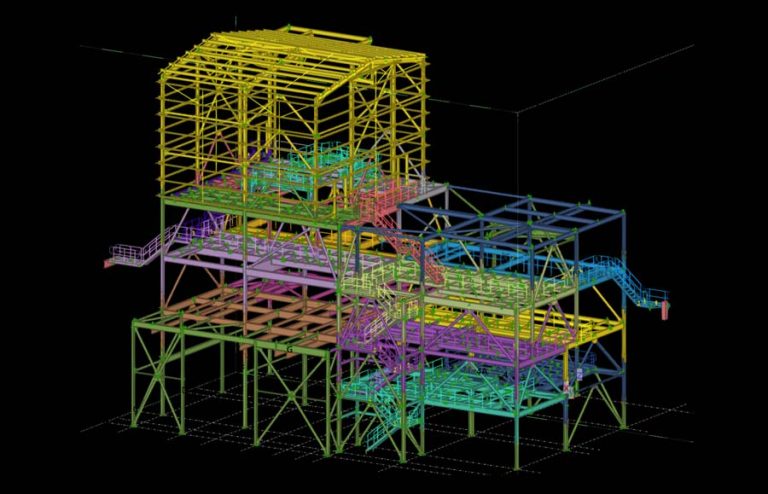

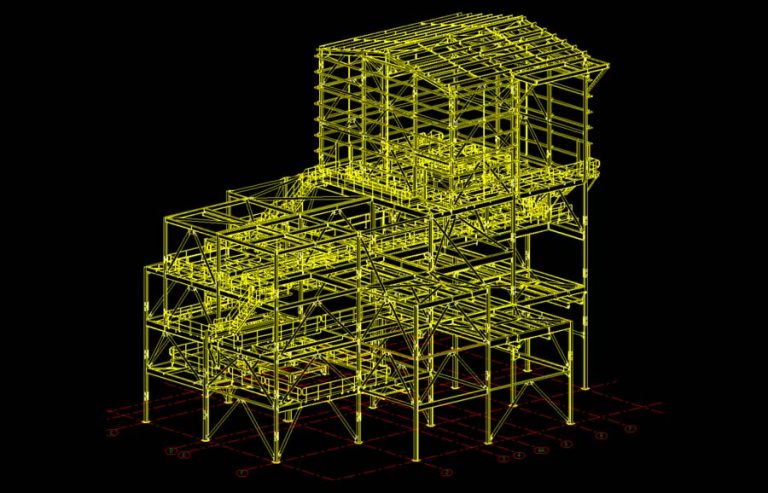

The project scope included bins, chutes, conveyors, and transfer buildings. K Neumayer is completing the site installation and commissioning, as well as the bulk earthworks and full civil scope.

Together with our South African Steel Fabrication partner Viva Engineering, we were awarded the turnkey shop detailing, fabrication, corrosion protection, transport, and site installation of the Paste Plant in 2023.

This project consists of 1250 tons and over 4km of piping. The Rosh Pinah project is currently in execution.

(Namibia) 2021

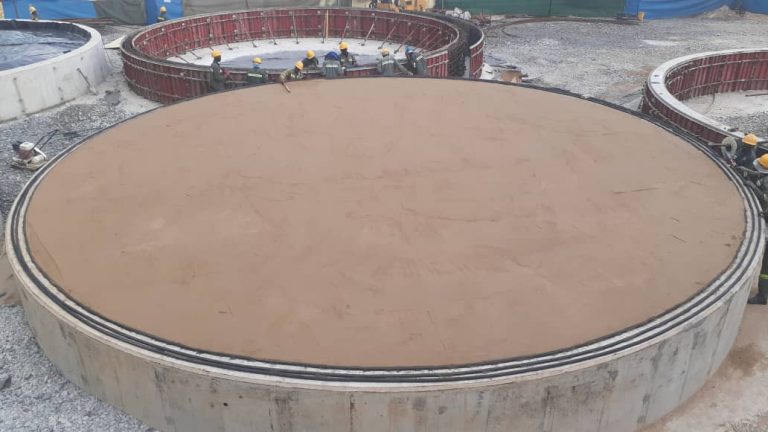

The Salt Wash Plant project required almost 70 000m³ of excavation, bulk backfill, and layerworks.

The accumulated structural steel and rebar used in the construction amounted to 200 tons.

This project was successfully completed in 2022.

Tailings Storage Facility

(Namibia) 2022

The TSF project required almost 700 000m³ of excavation and bulk backfill and layerworks. In addition, over 8km of underdrainage pipling and over 1000m³ of concrete was required. The project was successfully completed in 2022.